Henderson

Country: USA

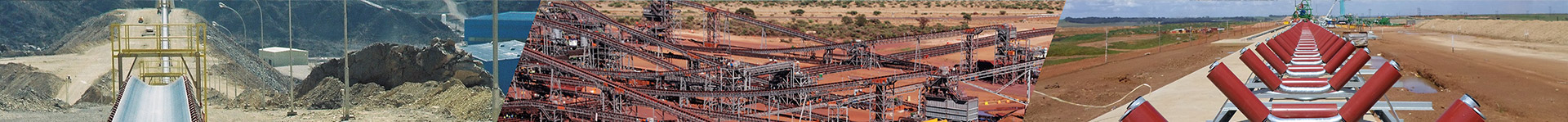

Located approximately 80 kilometres west of Denver, Colorado in the USA; the Henderson overland system is widely regarded as one of the most technically advanced conveyor systems in the world due to its energy efficiency and unique component design.

Completed in 1999, this project replaced the previous rail infrastructure—which transported molybdenum from the mine—with a three-flight conveyor system.

These three flights consist of the following conveyors:

- PC1 – a 1.2km high lift conveyor which transports ore from the underground crushing station to the end of the existing rail tunnel,

- PC2 – a 17km overland conveyor utilizing existing rail tunnels from the east side of the continental divide to the mill located on the west side, and

- PC3 – a 6.3km overland conveyor running from the tunnel portal to the mill, through a series of nine horizontal and vertical curves as well as inclines of up to 15 degrees.

Key Statistics

- Belt Width: 1200mm

- Belt Speed: 4.5 – 6.1 m/s

- Capacity: 2,270 Tph

Lorbrand conveyor idlers were selected for exclusive use on the project after extensive testing demonstrated their superior quality and low rolling resistance.

As a result of its significance and unique design, the Henderson project is now used as a case study in mining schools and institutions around the globe.