HDPE Rollers

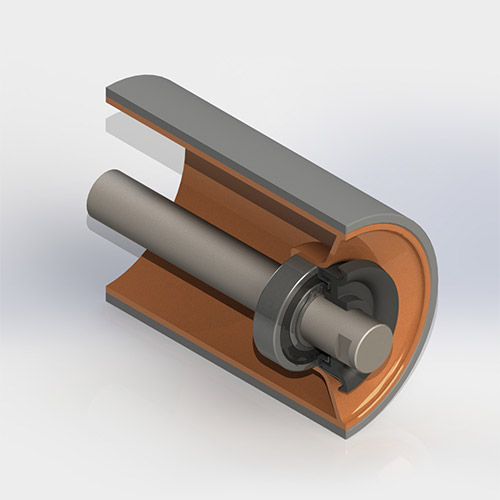

For use in low-noise applications, each HDPE roller combines the strength of Lorbrand’s standard welded steel body with the non-stick properties of a high-density polyethylene sleeve.

These rollers are so quiet that at belt speeds below 3 m/s, the running belt can barely be heard. This combination makes them strong, lightweight and suitable for high tonnage applications and conveyor belt systems greater than 1600mm wide.

Key Aspects

- Diameters – 127—300mm

- Roll Lengths – 150—2200mm

- TIR – Typically less than 0.3mm at roll ends

- Noise – Typically 5—10 dBA less than their steel equivalent

- Bearing Sizes – 6306 to 6310

- Material Specifications – High-grade HDPE as well as ultra-high-molecular-weight polyethylene (UHMWPE)

Please contact Lorbrand for information on our full product range.

| SERIES | DIAMETER (mm) | SHELL WALL (mm) | NOMINAL SHAFT DIAMETER (mm) | BEARING PART NO. | MIN BEARING DYNAMIC LOAD RATING (N) |

|---|---|---|---|---|---|

| 20 | 127 | 3.5 + 6.5 | 20 | 6204 – 2RS | 12 700 |

| 25 | 127 | 3.5 + 6.5 | 25 | 6205 – 2RS | 14 000 |

| 152 | 4 + 6.5 | ||||

| 159 | 4 + 10 | ||||

| 27 | 127 | 3.5 + 6.5 | 25 | 6305 – 2RS | 22 500 |

| 133 | 3.5 + 9.5 | ||||

| 152 | 4 + 6.5 | ||||

| 159 | 4 + 10 | ||||

| 32 | 127 | 3.5 + 6.5 | 30 | 6306 – 2RS | 28 100 |

| 133 | 3.5 + 9.5 | ||||

| 152 | 4 + 6.5 | ||||

| 159 | 4 + 10 | ||||

| 178 | 4 + 6.5 | ||||

| 35 | 152 | 6 + 6.5 | 35 | 6307 – 2RS | 33 200 |

| 159 | 6 + 10 | ||||

| 178 | 6 + 6.5 | ||||

| 40 | 152 | 6 + 6.5 | 40 | 6308 – 2RS | 41 000 |

| 159 | 6 + 10 | ||||

| 178 | 6 + 6.5 | ||||

| 193 | 6 + 7.5 | ||||

| 219 | 6 + 13 | ||||

| 45 | 178 | 6 + 6.5 | 45 | 6309 – 2RS | 52 700 |

| 193 | 6 + 7.5 | ||||

| 50 | 193 | 6 + 7.5 | 50 | 6310 – 2RS | 61 800 |

Deep groove double sealed or shielded bearings, of tolerance class C3 and C4, are used. This allows for a larger amount of angular misalignment at the bearing than other bearing designs and classes.

Shell Assembly

Only high-quality tube specially manufactured for conveyor idlers is used and conforms to SABS 657/3 (1980). High-grade engineering-class HDPE tube is pressed over steel tube and machined to ensure low TIR.

Steel Shaft

Manufactured from steel which complies with the requirements for grade 070 M20 of BS 970-1. Shaft diameter tolerance adheres to bearing manufacturer standards and ensures a js6 fit. Shaft end slots are machined to customer standards.

Hollow Shaft

Stepped lightweight hollow steel shafts, equivalent in strength and rigidity to solid shafts, are available on request.

Bearing Housing

Manufactured from deep drawing material KHR1. Housings are pressed and MI -welded to the inside of the tube.

Corrosion Protection

An external coat of self-etching primer is applied to roll ends only, unless otherwise specified.

Circular Movement Tolerance (TIR)

TIR does not exceed 0,3mm measured at a distance of 25mm from the roller end face. Actual TIR values are less and can be verified by referencing historical data.

| ROLLER FACE LENGTH (MM) | TIR |

|---|---|

| ALL DIA’S | |

| Up to 536 | 0.3 |

| 586 to 965 | 0.4 |

| 994 to 1 450 | 0.4 |

| 1 602 to 2 518 | 0.4 |