Conveyor Pulleys

With our state-of-the-art pulley facility, Lorbrand offers clients customised manufacturing solutions to meet their conveyor pulley needs. These include plate rolling, profiling, machining, line boring, sub-arc welding, stress relieving, sand blasting, static balancing and painting.

Our design capabilities also include the use of detailed Finite Element Analysis (FEA) using ANSYS software, as well as Lorbrand programs developed in-house.

The Lorbrand pulley manufacturing facility is ISO 9001:2015 accredited, ensuring all products are of the highest quality and for each pulley produced Lorbrand generates a databook containing the original design info, material certificates, inspection reports, test information, approved drawings and any other pertinent data.

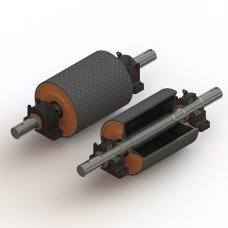

Our range of customisable pulleys include:

- Conventional pulleys (drive, tail, bend, snub)

- Slatted pulleys (self-cleaning)

- Internal bearing pulleys (static shaft)

- Apron feeder shaft assemblies

We also offer standard shaft locking elements and shrink fit shafts for special applications.